Introductionamong Custom plastic injection molding It has given great spiritual support to entrepreneurs, and more entrepreneurs will contribute to this industry in the future. https://bfymold.com/

PVC is one of the most widely used plastics in the world, prized for its versatility, durability, and cost-effectiveness. This blog post will delve into the world of PVC, exploring what it is, the different types of PVC plastics, the various manufacturing processes, and the environmental impact and recycling of PVC materials.

What Is PVC Materials?

Polyvinyl Chloride, commonly known as PVC, is a synthetic plastic polymer made from the polymerization of vinyl chloride. PVC is known for its durability, chemical resistance, and versatility, making it suitable for a wide range of applications, from construction materials to medical devices.

set of fittings for pvc pipes

PVC Materials

PVC can be produced in two basic forms:

Rigid PVC: Used for pipes, windows, and doors.

Flexible PVC: Used for cables, flooring, and soft products through the addition of plasticizers.

Its ability to be mixed with various additives gives it unique properties, making PVC a preferred choice in numerous industries.

The Different Types Of PVC Plastic Materials

PVC plastics can be broadly classified into three types based on their formulation and properties:

Type of PVC Characteristics Common Applications

Rigid PVC (uPVC) High strength, rigid, excellent chemical resistance, low cost Pipes, window frames, profiles, credit cards

Flexible PVC Soft, flexible, good insulation properties, resistant to abrasion Cable insulation, flooring, medical tubing, seals

CPVC (Chlorinated PVC) Improved thermal stability, better chemical resistance Hot water pipes, industrial liquid handling, fire sprinkler systems

PVC Characteristics and Common Applications

Rigid PVC (uPVC) is unplasticized PVC, which means it does not contain added plasticizers. It is hard and durable, making it ideal for structural applications.

Flexible PVC is made by adding plasticizers, which make the material more flexible and softer. This type is used in applications where flexibility is required, such as in tubing, insulation, and certain fabrics.

Chlorinated PVC (CPVC) is PVC that has been chlorinated via a chlorination reaction. The added chlorine content in CPVC makes it more heat-resistant and suitable for hot water pipes and industrial fluid handling.

Different Types Of PVC Plastic Materials Manufacturing Processes

Internal corners for groove PVC skirting boards

PVC Plastic Material Types

Several manufacturing processes are used to produce PVC products, each tailored to the specific type of PVC and its application:

Manufacturing Process Description Suitable for

Extrusion PVC resin is melted and formed into a continuous profile. Pipes, window frames, cable insulation, siding

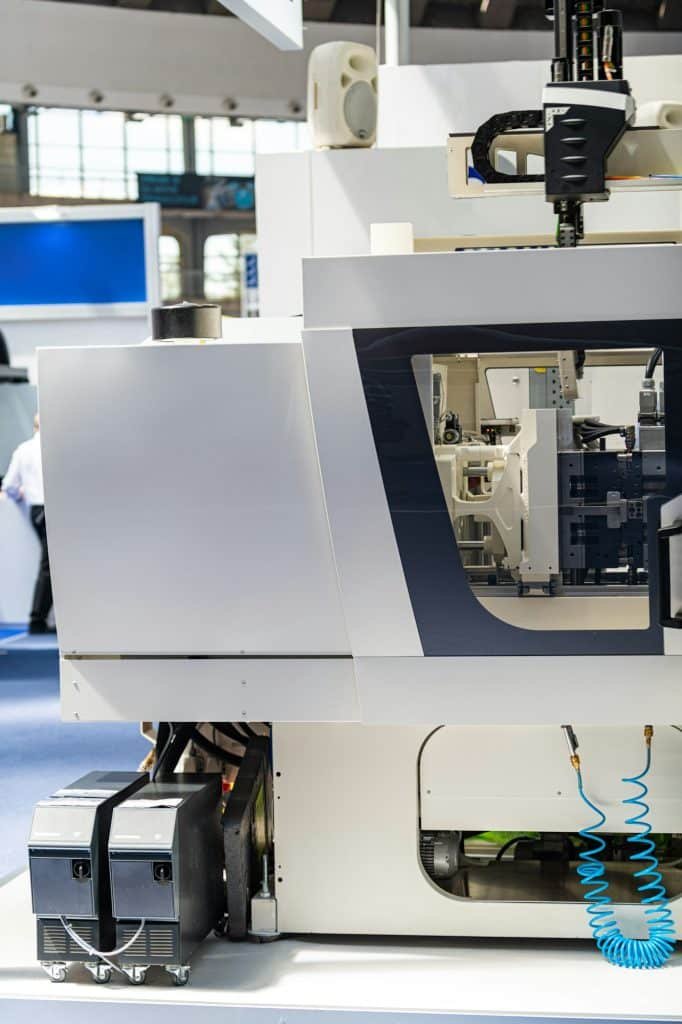

Injection Molding Molten PVC is injected into a mold to form intricate shapes. Fittings, valves, toys, containers

Blow Molding PVC is melted and extruded into a parison, which is then blown into a mold. Bottles, hollow containers, automotive parts

Calendaring PVC is rolled into thin sheets or films. Floor coverings, wall coverings, synthetic leather

Coating and Dipping PVC is dissolved or melted and then applied to a surface or dipped to form a coating. Gloves, tool handles, fabric coatings

PVC Plastic Manufacturing Processes

Extrusion: In this process, PVC resin is heated and melted, then pushed through a die to create continuous shapes like pipes, tubes, or window frames. This method is particularly suited for products that require long lengths and uniform cross-sections.

Injection Molding: This process involves injecting molten PVC into a mold cavity to form complex shapes and designs. Injection molding is ideal for producing items like pipe fittings, containers, and various automotive parts.

Blow Molding: PVC is heated and extruded into a parison (a tube-like piece), which is then inflated into a mold to create hollow objects such as bottles and tanks.

Calendaring: In this process, PVC is passed through heated rollers to create thin sheets or films. Calendaring is commonly used to make products like vinyl flooring, shower curtains, and synthetic leather.

Coating and Dipping: PVC can be melted or dissolved and then applied as a coating on other materials. This process is used to make products like protective gloves and coated fabrics.

Environmental Impact and Recycling of PVC Materials

PVC¡¯s production, use, and disposal raise significant environmental concerns due to its chemical composition and additives. However, the recycling of PVC can help mitigate some of these impacts:

Production Impact: The production of PVC involves chlorine, which can produce toxic byproducts like dioxins. The presence of plasticizers and stabilizers (like lead or cadmium) in some PVC types can also be hazardous.

Usage Impact: During use, PVC products are generally stable and safe. However, when burned or exposed to high temperatures, PVC can release toxic fumes.

Recycling: PVC is highly recyclable and can be mechanically recycled to